Why You Need Specialist Welding Inspection Racine for Your Projects

Why You Need Specialist Welding Inspection Racine for Your Projects

Blog Article

Equipping Your Service With Customized Welding Inspection Provider for each Job

In the world of service operations, the value of welding examinations customized to certain project demands can not be overemphasized. Personalized evaluation plans not just offer as a critical component of quality assurance but also play a critical role in ensuring the structural stability and security of completion item. By diving into the nuanced aspects of welding inspection services, businesses can unlock a realm of advantages that extend beyond mere conformity. Whether it be small-scale tasks that require accuracy or big endeavors requiring streamlined effectiveness, the tailored strategy to welding assessments stands as a cornerstone for success.

Value of Tailored Welding Inspections

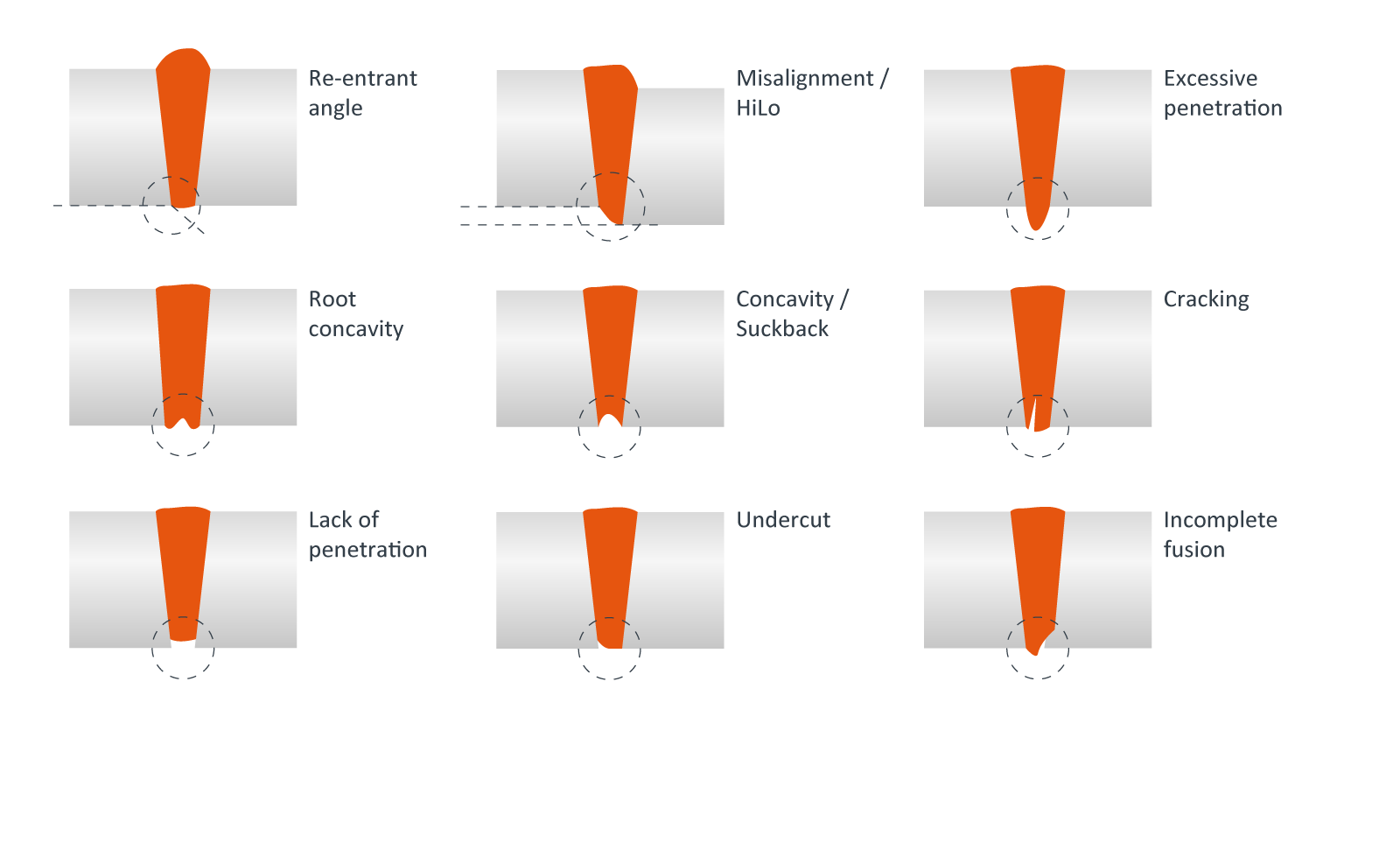

Customized welding evaluations play a crucial function in making sure the high quality and honesty of welds in various markets. These specialized inspections are customized to meet the details needs of each task, taking into consideration elements such as the sort of products being bonded, the welding method utilized, and the sector standards that require to be stuck to. By customizing the assessment procedure, possible flaws and issues can be determined and resolved early on, stopping expensive rework or failings down the line.

One secret relevance of customized welding assessments is their capability to ensure compliance with sector regulations and requirements. Different sectors have differing needs when it pertains to welding top quality, and tailored inspections assist organizations satisfy these standards properly. In addition, customized examinations help enhance general performance and efficiency by improving the assessment procedure to concentrate on the most vital locations. This targeted technique not just conserves time but likewise boosts the total quality of the welding job, leading to much safer and extra reputable final product.

Advantages of Custom-made Assessment Plans

Personalized examination strategies offer services a critical benefit by exactly aligning evaluation processes with the unique demands of each welding project. By customizing examination plans to suit the details requirements of a job, companies can make sure that all essential aspects are extensively taken a look at, thereby decreasing the danger of welding issues and guaranteeing compliance with industry requirements. One of the primary benefits of personalized examination plans is the boosted effectiveness they bring to the welding process. By concentrating on the most critical areas of a project, inspectors can designate their time and sources more efficiently, bring about faster project conclusion and lowered downtime.

Personalized examination strategies offer services a critical benefit by exactly aligning evaluation processes with the unique demands of each welding project. By customizing examination plans to suit the details requirements of a job, companies can make sure that all essential aspects are extensively taken a look at, thereby decreasing the danger of welding issues and guaranteeing compliance with industry requirements. One of the primary benefits of personalized examination plans is the boosted effectiveness they bring to the welding process. By concentrating on the most critical areas of a project, inspectors can designate their time and sources more efficiently, bring about faster project conclusion and lowered downtime. In addition, tailored inspection plans help organizations conserve prices over time by avoiding rework and decreasing the probability of project hold-ups. By capturing possible issues beforehand with personalized evaluations, companies can address them promptly, preventing expensive errors down the line. Additionally, customized assessment strategies can boost total job quality by offering an extra extensive and thorough analysis of welding procedures, products, and workmanship. This, in turn, can bring about improved consumer contentment and a more powerful online reputation for delivering top notch welding tasks.

Tailored Providers for Small-Scale Projects

For small welding jobs, specialized assessment services his response can be tailored to meet the certain demands and restrictions of the project extent - Welding Inspection Racine. While bigger tasks often have much more standardized evaluation processes, small projects call for a much more focused and personalized strategy because of their distinct attributes

In small-scale projects, every weld is essential, and also small flaws can have considerable consequences. Customized welding inspection services for these projects include an extensive understanding of the job goals, materials utilized, welding methods, and sector regulations. By tailoring the evaluation strategy to fit the range and intricacy of the project, potential problems can be recognized early, leading to boosted weld high quality and overall task success.

Additionally, tailored services for small-scale projects can aid enhance sources and reduce costs. By focusing assessment efforts on areas that matter most for the particular task, unneeded assessments can be stayed clear of, conserving both money and time. This targeted strategy ensures that the evaluation process is effective, effective, and ultimately adds to the effective conclusion of small-scale welding jobs.

Additionally, tailored services for small-scale projects can aid enhance sources and reduce costs. By focusing assessment efforts on areas that matter most for the particular task, unneeded assessments can be stayed clear of, conserving both money and time. This targeted strategy ensures that the evaluation process is effective, effective, and ultimately adds to the effective conclusion of small-scale welding jobs.Enhancing Performance in Big Projects

In the world of large-scale welding jobs, the emphasis shifts in the direction of simplifying evaluation processes to enhance overall efficiency and check my reference job success. Employing sophisticated assessment strategies, such as automated welding inspection systems and real-time monitoring tools, can significantly lower assessment times while boosting accuracy.

Additionally, establishing clear interaction networks and procedures in between examination teams, project managers, and welders is important for ensuring that inspections are carried out promptly which any kind of problems are immediately dealt with. Applying an organized strategy to evaluation organizing, prioritizing vital welds, and alloting sources successfully can aid avoid bottlenecks and maintain the project on track. Continual training and upskilling of evaluation employees additionally play a vital duty in enhancing efficiency in huge jobs, making sure that inspectors are equipped with the current expertise and methods to do their duties efficiently.

Ensuring Compliance and Service Security

Maintaining strict adherence to welding policies and industry criteria is extremely important for guarding service rate of interests and making certain functional conformity. By focusing on compliance, organizations can reduce risks, prevent expensive penalties, and copyright their reputation within the market. Welding examination solutions play a critical duty in making sure that all welding processes meet the required standards and codes, giving companies with the assurance that their jobs are implemented in a secure and certified fashion.

In addition, compliance with welding regulations is not nearly meeting legal needs; it is also about making sure the safety of personnel, the general public, and the environment. Non-compliance can bring about crashes, architectural failings, and environmental risks, every one of which can have extreme repercussions for an organization's lower line and track record. By investing in tailored welding assessment solutions, businesses can proactively address and determine compliance problems prior to they intensify, thus protecting their rate of interests and cultivating a society of security and high quality within the organization.

Verdict

In final thought, tailored welding assessment services play a vital duty in equipping companies by guaranteeing top quality, compliance, and performance in jobs of all dimensions. Welding Inspection Racine. Investing in customized welding inspections is a critical decision for businesses looking to attain quality in their welding procedures.

In addition, customized evaluations aid boost total efficiency and efficiency by enhancing the evaluation process to concentrate on the most essential locations.Customized assessment strategies use businesses a tactical advantage by exactly lining up examination processes with the special demands of each welding project. By focusing navigate to this site inspection efforts on locations that matter most for the certain job, unnecessary evaluations can be avoided, saving both time and cash. Using advanced assessment techniques, such as automated welding examination systems and real-time tracking tools, can substantially lower assessment times while boosting precision.Moreover, developing clear interaction channels and procedures in between examination groups, task supervisors, and welders is necessary for guaranteeing that assessments are carried out quickly and that any type of concerns are quickly dealt with.

Report this page